they are also opening a production facility in a few yearsRussia has two 180nm-90nm fabs. One which can produce at 3000 wafers per month, and another which can produce at 15000 wafers per month. 200mm wafers. Each wafer might be able to have dozens or even hundreds of chips depending on die area.

Well at least in theory since the largest fab is supposedly mostly producing chips for smartcards at like 250nm.

The smaller fab has produced several 90nm chip designs including the Elbrus-2SM that I mentioned. Even 3000 wafers per month is more than enough to produce all the logic chips they might need for the military.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Russian Military News, Reports, Data, etc.

- Thread starter tphuang

- Start date

That is pure vaporware. They still haven't even made the tools. There were concrete plans to build a 28nm fab with 300mm wafers in Russia. Funded and in construction. They had already cleared the construction site. But with the recent sanctions they can't buy the equipment from the West so I doubt that will go anywhere.

Some of those materials can be sourced in Russia already. Others might be available but not have the required purity. They can work on that. Others have alternative sources outside the West. Russia's production facilities are old enough that there are plenty of alternative sources for these things. Mikron was put on the US entity list in 2016.Do you know who their wafer equipment manufacturing suppliers?

If these are Western companies then they might soon run into a lack of spare parts and input materials like wafers, photoresists, etching chemicals, etc.

Last edited:

That is pure vaporware. They still haven't even made the tools. There were concrete plans to build a 28nm fab with 300mm wafers in Russia. Funded and in construction. They had already cleared the construction site. But with the recent sanctions they can't buy the equipment from the West so I doubt that will go anywhere.

In Russia, the development of domestic lithographic scanners has begun — their production will begin in 2025-2026

10.02.2022 [16:28], Gennady DetinichAt the end of last year 5.7 billion rubles for the development of domestic lithographic scanners. Recently it became known that the Zelenograd Nanotechnology Center (ZNTC) has started project work on this order. Learn more about the center's project resource plans Kovalev, General Director of the ZSTC, said.

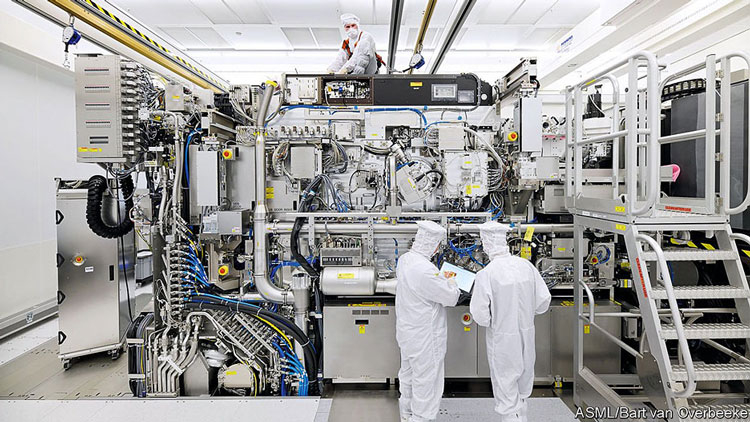

An example of a photolithographic scanner manufactured by ASML. Image Source: ASML

Serial production of 350 nm photolithographs is expected to start in 2025. A ready-made semiconductor laser of domestic production will be used for installation. It is possible that in the future lasers of Zelenograd companies may also be used for this purpose. According to the contract, the scanner design and its prototype should be ready by the end of 2024, including all documentation for the launch of mass production of the installation.

From the tender documentation, it follows that the 350-nm scanner will be a 3.5-ton installation with dimensions of 2 × 2.6 × 2.5 m and a control complex with dimensions of 2 × 0.8 × 1.6 m. The unit is focused on processing 150-and 200-mm silicon substrates.

Development of the 130-nm scanner will be completed about a year later. For this scanner, a domestic 193-nm laser will be created from scratch in order to get away from imported components, in particular, from the lasers of the American company Cyber, which are now widely used in Russian semiconductor factories. For this reason, the completion of the 130-nm scanner project will take a little longer.

The project of a 130-nm scanner with the ability to process up to hundreds of 200-mm plates per hour will be put into mass production at the end of 2026. In the future, the plant will be upgraded to produce chips with lower technological standards up to 65 nm. Reducing the size of the topology, among other things, will be achieved by double exposure. The main plate size for this scanner will be 200 mm substrate with optional use of 150 mm substrates.

According to the developers, the vast majority of orders for the production of chips in the world lies in the range from 250 to 65 nm, so there is no point in chasing tens and units of nanometers. The main thing for Russia in this project is to avoid possible sanctions on the supply of industrial semiconductor equipment. Own production of scanners can protect the country's electronics industry.

The serial scanner manufacturer has not yet been selected. This may be ZNTC, Zelenograd companies, or Belarusian partners represented by Planar. In the USSR, lithographic scanners, which, by the way, still continue to work in Russian factories, were produced by the Minsk plant "Planar". This practice may extend to the release of a new generation of scanners.

what tools? I think you were talking about their previous plan for the development. Which seems to have been stopped. Coordinates 55.98026011774556, 37.214472088231204.

but of course i think they have a big reason now to start their own production facility again dont you think?

Last edited:

A scanner aka lithography machine is a tool. One of the many tools they would need to have a fab. Like I said, the Russians now have a plan to make their own tools, and then later make a fab. They can't buy tools from the West anymore because of the sanctions. This is all vaporware because said tools don't exist yet.what tools? I think you were talking about their previous plan for the development. Which seems to have been stopped. Coordinates 55.98026011774556, 37.214472088231204.

but of course i think they have a big reason now to start their own production facility again dont you think?

Before the latest sanctions hit the Russians had a plan to make a 28nm fab with 300mm wafers with Western tools. But because of the sanctions that should not be going anywhere soon.

They should buy Chinese tools in the meantime if they want to spin up a domestic industry. Current SMEE is better than even their projected litho projects. They haven't even gotten into etch and deposition, maybe they're just going to buy them.A scanner aka lithography machine is a tool. One of the many tools they would need to have a fab. Like I said, the Russians now have a plan to make their own tools, and then later make a fab. They can't buy tools from the West anymore because of the sanctions. This is all vaporware because said tools don't exist yet.

Before the latest sanctions hit the Russians had a plan to make a 28nm fab with 300mm wafers with Western tools. But because of the sanctions that should not be going anywhere soon.

The big limitation is Chinese toolmaker throughput to match both domestic and foreign demand.

plawolf

Lieutenant General

This article might explain the lack of targetting pods and PGM's in the VKS. Russia has almost a complete lack of ability to produce micro electronics. The extent that Russian weapons are reliant on foreign electronic components is much larger than previously thought. Mindful of the fact that the source for this is Ukraine and NATO countries you do need to take some of the things said in the article with a pinch of salt. But the truth may not be that far off.

Seems like a load of BS copium to me. If the Russians were that desperate, they could have bought all the components from China and stuffed them in a Russian built shell.

I think the part of issue is one of doctrine and mission set. Essentially, conventionally, the VKS were set up to deny NATO air superiority. So long as they can prevent NATO air power from pounding Russian ground forces to dust, they are confident their own ground forces would crush NATO ground forces in a fair fight. And I generally agree with that assessment.

The other major role the VKS was set up to do was strategic nuclear bombing, which probably eats up all their ‘bombing’ budget and leaves very little left for tactical bombing.

However, as with their ground forces ‘modernisation’, I think another significant problem is that they also tried to do their Air Force modernisation on the cheap.

They got modern targeting computers on their newer fighters and realised they could do Gulf War I standard ‘precision’ bombing with dumb bombs, so they didn’t really bother to purchase much in the way of PGMs and target pods that they offered for export.

That may be the case when you are bombing Xs in fields that don’t shoot back, but doing so in real life put your delivery aircraft at significant risk from enemy air defences, especially when it looks like they also didn’t invest in the kinds of SEAD and DEAD capabilities that the US had back in 90/91, which was the basis on which they were able to mount the air campaign.

That’s why we had so many high end Flankers shot down (needlessly) early in the war, and probably why the VKS has been conspicuously absent from the war ever since, apart from low level Su25 attacks.

This does fit with a telling story Guancha told during one of their talks (sorry, can’t remember which one) where a PLAAF pilot was puzzled by the total lack of PGM use during joint exercises with the Russians.

When he queried the Russians about it, they asked him back about how many PGMs he had dropped in training, which he told them, and was told in turn that the number of PGMs he had used was more than the sum total the entire Russian Air Force had dropped that year.

Chinese equipment contain lots of foreign components (90% in some according to a research report). The equipment makers most likely don’t want to upset their European/Japanese suppliers.They should buy Chinese tools in the meantime if they want to spin up a domestic industry. Current SMEE is better than even their projected litho projects. They haven't even gotten into etch and deposition, maybe they're just going to buy them.

The big limitation is Chinese toolmaker throughput to match both domestic and foreign demand.

There is no doubt that the Russians are unable to manufacture the more sophisticated chips. They do have years to prepare for this war, so it is highly unlikely that they don't have a stockpile of all the chips that they needed for many years of production for their military hardware. The amount of chips required are relatively small compared to the consumer product needs so this purchase in peacetime would not even register and the cost of stockpiling these chips are not that big a drain on the Russian finances. All this talk about the Russians scrapping their washing machines for their chips are just nonsense. To produce a weapon of some kind that requires chips, you can't just substitute any chip from any toaster and expect the thing to still work. They have done extensive testing to ensure that a particular combination of chips work with that weapon. Even if somehow, against all odds, that they have failed to procure enough chips for a particular weapon, it is simply cheaper to smuggle these chips from the West compared to having to rewrite the software, re-do the testing, all for the ability to use a few chips off washing machines.Seems like a load of BS copium to me. If the Russians were that desperate, they could have bought all the components from China and stuffed them in a Russian built shell.

I think the part of issue is one of doctrine and mission set. Essentially, conventionally, the VKS were set up to deny NATO air superiority. So long as they can prevent NATO air power from pounding Russian ground forces to dust, they are confident their own ground forces would crush NATO ground forces in a fair fight. And I generally agree with that assessment.

The other major role the VKS was set up to do was strategic nuclear bombing, which probably eats up all their ‘bombing’ budget and leaves very little left for tactical bombing.

However, as with their ground forces ‘modernisation’, I think another significant problem is that they also tried to do their Air Force modernisation on the cheap.

They got modern targeting computers on their newer fighters and realised they could do Gulf War I standard ‘precision’ bombing with dumb bombs, so they didn’t really bother to purchase much in the way of PGMs and target pods that they offered for export.

That may be the case when you are bombing Xs in fields that don’t shoot back, but doing so in real life put your delivery aircraft at significant risk from enemy air defences, especially when it looks like they also didn’t invest in the kinds of SEAD and DEAD capabilities that the US had back in 90/91, which was the basis on which they were able to mount the air campaign.

That’s why we had so many high end Flankers shot down (needlessly) early in the war, and probably why the VKS has been conspicuously absent from the war ever since, apart from low level Su25 attacks.

This does fit with a telling story Guancha told during one of their talks (sorry, can’t remember which one) where a PLAAF pilot was puzzled by the total lack of PGM use during joint exercises with the Russians.

When he queried the Russians about it, they asked him back about how many PGMs he had dropped in training, which he told them, and was told in turn that the number of PGMs he had used was more than the sum total the entire Russian Air Force had dropped that year.

Show the report then. Sometimes the report doesn't say what you think it says.Chinese equipment contain lots of foreign components (90% in some according to a research report). The equipment makers most likely don’t want to upset their European/Japanese suppliers.

Show the report then. Sometimes the report doesn't say what you think it says.

"据北方华创统计,半导体设备零部件的国产化率约10%-30%。"capability up until 3nm. 7nm verified.

同时,上海凯世通超越7nm离子注入平台已通过客户验证并取得验收。

....

据了解,凯世通承担了多项国家重大专项和科技项目,获得的知识产权全部归凯世通所有。在2016年已突破14nm工艺中离子注入机研发的最大技术障碍,目前凯世通离子注入机的工艺已实现28nm至3nm全面覆盖。”万业企业副总裁兼董秘周伟芳在接受第一财经专访时透露。

Only 10-30% of components in domestic semiconductor manufacturing equipment are from domestic sources