Last edited:

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese semiconductor thread II

- Thread starter vincent

- Start date

Dutch minister mastermind behind Nexperia seizure admits he was "blindsided" by China decision to block company's chip from leaving China.

@tokenanalyst you are right, they didn't know the basics that Nexperia China fabs was so important in the global supply chain of packaging and wafers.

@tokenanalyst you are right, they didn't know the basics that Nexperia China fabs was so important in the global supply chain of packaging and wafers.

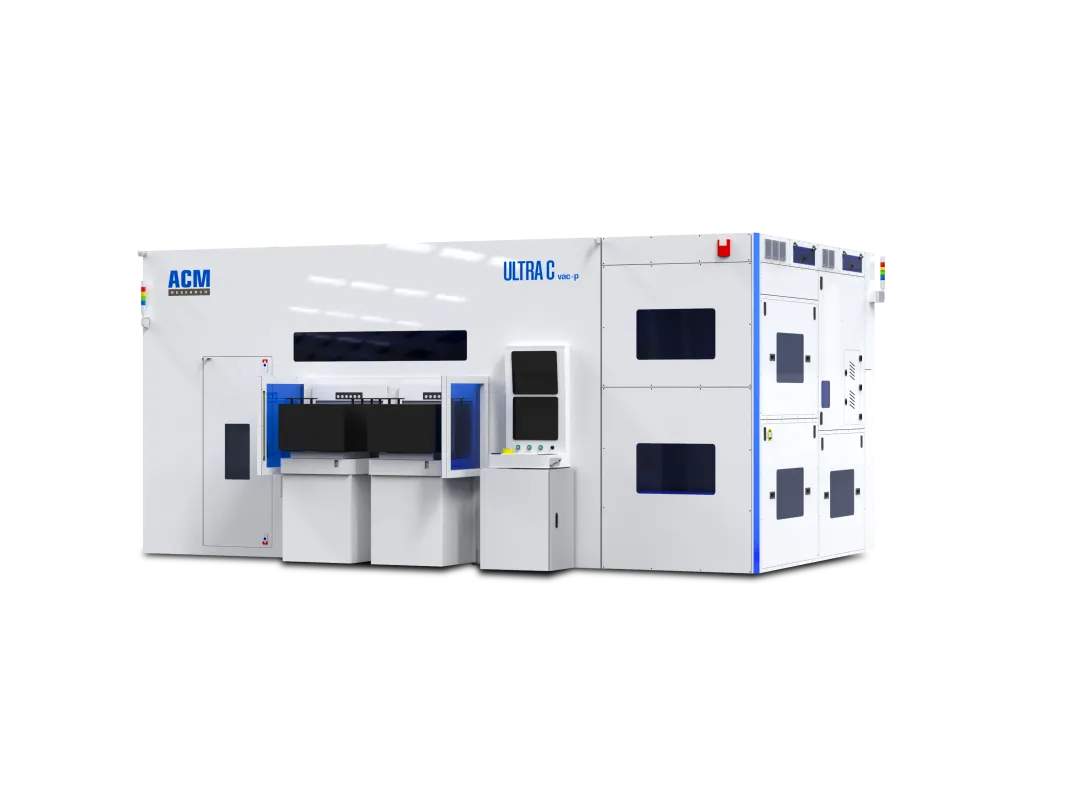

Shengmei Semiconductor's Ultra C vac-p flux cleaning equipment won a global technology award in the field of cleaning equipment.

The award ceremony was held on November 18, 2025, during the productronica trade fair in Munich, Germany. ACM Research Chairman Wang Hui, North American Sales VP Jim Straus, and European CTO Sallyann Henry attended the ceremony and accepted this international honor, highlighting the company's continued progress in providing cutting-edge cleaning solutions for advanced packaging technologies.

ACM Research General Manager Wang Jian stated :

"We are deeply honored that our globally proprietary Ultra C vac-p has won the 2025 Global Technology Awards in the Cleaning Equipment category. Driven by artificial intelligence, data centers, and autonomous vehicles, emerging fan-out panel-level packaging technology can improve computing power, reduce latency, and increase bandwidth. This technology is rapidly becoming a critical solution, integrating multiple chips, passive components, and interconnects into a single package on a panel, providing greater flexibility, scalability, and cost-effectiveness. This award reflects ACM Research's commitment to providing professional cleaning solutions to address the severe challenges in panel-level packaging." Ultra C vac-p, with its vacuum technology and proprietary IPA drying process, ensures process precision and reliability, helping manufacturers improve yield and device performance.

Launched in July 2024, Ultra C vac-p, an advanced flux cleaning technology for panel-level packaging addresses a key technical challenge in advanced packaging: flux residue removal before underfill. Built on ACM Research's proven platform in wafer-level packaging and high-bandwidth memory cleaning, this equipment aims to help manufacturers transitioning to panel-level packaging effectively reduce costs and improve yield.

Traditional flux cleaning methods often perform poorly with small bump pitches and large chips due to surface tension effects and insufficient liquid penetration. Ultra C vac-p utilizes vacuum technology to enhance the penetration of the cleaning liquid, helping it reach various gaps in large panel substrates and creating conditions for comprehensive and uniform cleaning. Combined with ACM Research's proprietary IPA drying technology, the system provides a complete cleaning process that effectively removes residues and reduces voids that could impair device performance.

As the industry rapidly moves towards more complex 2.5D and 3D architectures, Ultra C vac-p has demonstrated stable cleaning performance in complex panel designs and chip applications. Its superior performance further solidifies ACM Research's industry reputation for providing high-precision, high-reliability cleaning solutions for next-generation advanced packaging. This recognition of Ultra C vac-p,

leading the future of advanced packaging cleaning technology reflects ACM Research's unwavering commitment to improving advanced packaging cleaning technologies to support global semiconductor manufacturers in achieving higher yields, lower operating costs, and scalable growth.

While ACM Research continues to expand its advanced packaging portfolio, the company remains focused on developing solutions that meet increasingly demanding process and performance requirements, providing robust support for the realization of next-generation device architectures through reliable, high-precision cleaning technologies.

According to data from the General Administration of Customs, China's chip exports from January to October 2025 reached $162.1 billion, surpassing the total of $159.6 billion for the entire year of 2024.

The export value has increased by over $100 billion compared to 2016, before the trade war began.

The export value has increased by over $100 billion compared to 2016, before the trade war began.

The current surge in DRAM prices reminds me of the SSD price surge two or three years ago. YMTC expanded significantly in the Chinese consumer market during that time by offering lower prices with good quality. Now, it presents another opportunity for CXMT and YMTC.

Naura Technology Group is accelerating its expansion into the HBM chip manufacturing market, launching several core equipment products.

Naura Technology Group Co., Ltd. stated to investors on its interactive platform that with the rapid growth in demand for high-bandwidth memory (HBM), the demand for related process equipment is also continuously increasing. The company can provide a variety of core equipment in the HBM chip manufacturing field, including deep silicon etching, thin film deposition, thermal processing, wet cleaning, and electroplating, fully supporting HBM TSV (Through Silicon Via) and stacked packaging manufacturing processes.

HBM, as a high-performance memory technology, is widely used in data centers, artificial intelligence, and high-performance computing, and has a promising market prospect. As AI chips increasingly demand higher computing performance and lower power consumption, HBM technology has become a standard feature of GPUs and AI accelerators, driving the rapid development of advanced packaging (such as CoWoS) and TSV technologies.

As a leading domestic semiconductor equipment platform company, Naura Technology completed its acquisition of a controlling stake in Sinyuan Microelectronics in the first half of 2025, further completing its front-end process portfolio for coating, developing, and bonding equipment. The company's main products cover core process equipment for etching, thin film deposition, thermal processing, wet processing, and ion implantation. In the first half of 2025, revenue from thermal processing equipment exceeded RMB 1 billion, and revenue from wet processing equipment exceeded RMB 500 million (excluding Sinyuan Microelectronics). Shipments of etching, vertical furnace, and PVD equipment all exceeded 1,000 units.

In addition to Naura Technology Group, companies such as Topway Technology, Huahai Qingke, Shengmei Shanghai, and Jingyi Equipment are also actively expanding into the fields of HBM and advanced packaging, providing equipment for CMP, panel-level electroplating, edge etching, etc., to accelerate the localization process.

HBM, as a high-performance memory technology, is widely used in data centers, artificial intelligence, and high-performance computing, and has a promising market prospect. As AI chips increasingly demand higher computing performance and lower power consumption, HBM technology has become a standard feature of GPUs and AI accelerators, driving the rapid development of advanced packaging (such as CoWoS) and TSV technologies.

As a leading domestic semiconductor equipment platform company, Naura Technology completed its acquisition of a controlling stake in Sinyuan Microelectronics in the first half of 2025, further completing its front-end process portfolio for coating, developing, and bonding equipment. The company's main products cover core process equipment for etching, thin film deposition, thermal processing, wet processing, and ion implantation. In the first half of 2025, revenue from thermal processing equipment exceeded RMB 1 billion, and revenue from wet processing equipment exceeded RMB 500 million (excluding Sinyuan Microelectronics). Shipments of etching, vertical furnace, and PVD equipment all exceeded 1,000 units.

In addition to Naura Technology Group, companies such as Topway Technology, Huahai Qingke, Shengmei Shanghai, and Jingyi Equipment are also actively expanding into the fields of HBM and advanced packaging, providing equipment for CMP, panel-level electroplating, edge etching, etc., to accelerate the localization process.

Phytium Tengyun S5000C-M Domestically produced 64 cores processor.

Phytium has achieved a major breakthrough by having its domestically produced 64-core ARM CPU, the Tengyun S5000C-M, selected for China Mobile’s 5G extended pico base station procurement — with an order of 8,000 units. This marks the first large-scale deployment of a domestically developed CPU in 5G infrastructure, ending long-standing foreign dominance.

The Tengyun S5000C-M is tailored for cost-effective, low-power indoor coverage in challenging environments (e.g., blind spots), offering advantages like flexible deployment, easy maintenance, and scalability. It supports configurations such as 4T4R and 2T2R, enables virtualization and containerization, and is designed with an open architecture to support future evolution into 5G-A and readiness for 6G.

Key performance highlights:

- Double the single-core computing power compared to previous versions

- 40% lower power consumption than x86 platforms

- Secure, independent supply chain

- Enhanced PCIe resources (upgraded to 96 lanes in PCIe 5.0)

Originally designed with a 7nm process and up to 80 cores, the final version uses the FTC862 core (64 cores, max clock speed 2.3GHz), resulting in a ~15% performance drop due to process and design constraints including reduced L3 cache, lower DDR5 frequency, and limited PCIe lanes.

Despite these trade-offs, Phytium overcame industry challenges like complex protocol simulation and hardware acceleration through joint R&D and deep customization with China Mobile. This milestone signifies a significant step toward technological self-reliance in China’s 5G infrastructure.

Despite these trade-offs, Phytium overcame industry challenges like complex protocol simulation and hardware acceleration through joint R&D and deep customization with China Mobile. This milestone signifies a significant step toward technological self-reliance in China’s 5G infrastructure.

This is why Europe has been declining for so long. They are led by morons put in place by America with only one criteria, to be America's puppet.

This is why I can't take any European who talks about politics seriously.

Has there been a full benchmark test done for Kirin 9030 that is not using Zhuyitong or any other emulation so that we can compare if the claim of 40% improvement is true or not?