Hendrik_2000

Lieutenant General

Introducing little known company Sany headquarter in Changsha , Hunnan that this year will eclipse Caterpillar to become the largest producer of excavator,front loader via Taishang. See how they improve efficiency with robot.

Caterpillar used to be the king of excavator. I don;t think they ever form joint venture with Sany So those accusation of stealing is misplaced.China become formidable competitor largely because of continuing investment in R&D ,modern production facility, and growing domestic market. Starting as welding rod company Sany mushroom into one of the biggest off road machinery

It achieve notoriety because

During the , a crane manufactured by SANY was used in rescuing the Chilean miners. A pump from the company was donated to the to assist with the emergency response to the .

In 2011, Sany signed several contracts to open new manufacturing centers, the most important of them include the and centers, and the fifth international equipment plant in , the latter with an investment of US$200 million

Sany eyes bigger slice of global heavy equipment market

By CGTN's Yan Qiong

2018-08-05 13:45 GMT+8

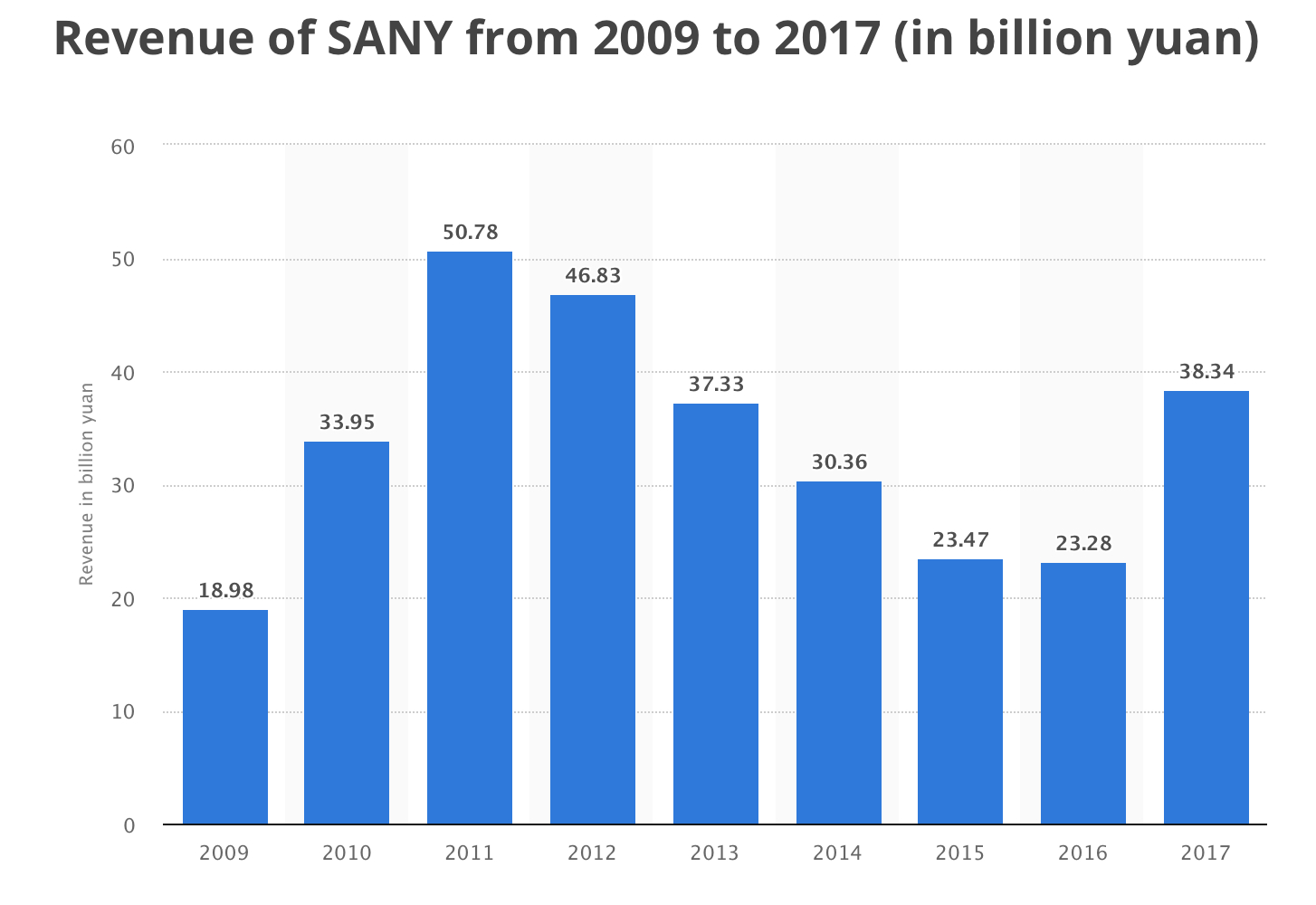

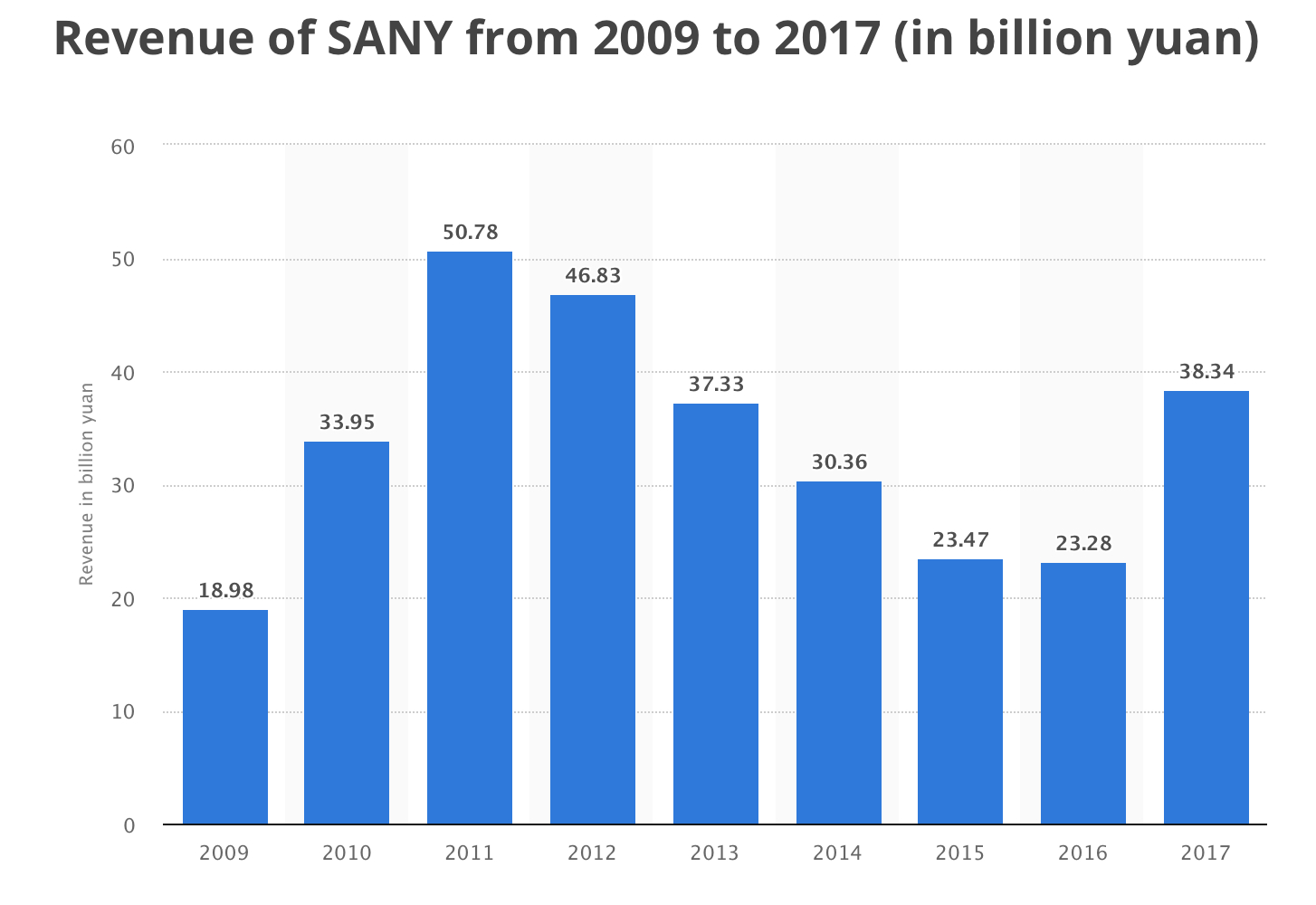

At a Sany facility in the city of Changsha city in central China’s Hunan Province, where an array of excavators, cranes, and concrete machinery is displayed, Liang Linhe, vice president of Sany Heavy Industry, told CGTN that “the forecasted revenue growth in 2018 is 50 percent, and by the end of this year, Sany will overtake Caterpillar in excavator sales for the first time.”

Liang Linhe, senior vice president of Sany Heavy Industry Co. /CGTN Photo

You may have never heard of Sany, one of China’s most important homegrown success stories, but the name is as big as Caterpillar in China, where it has rocketed from a company making welding materials in 1989 to becoming the biggest construction equipment manufacturer.

CGTN Photo

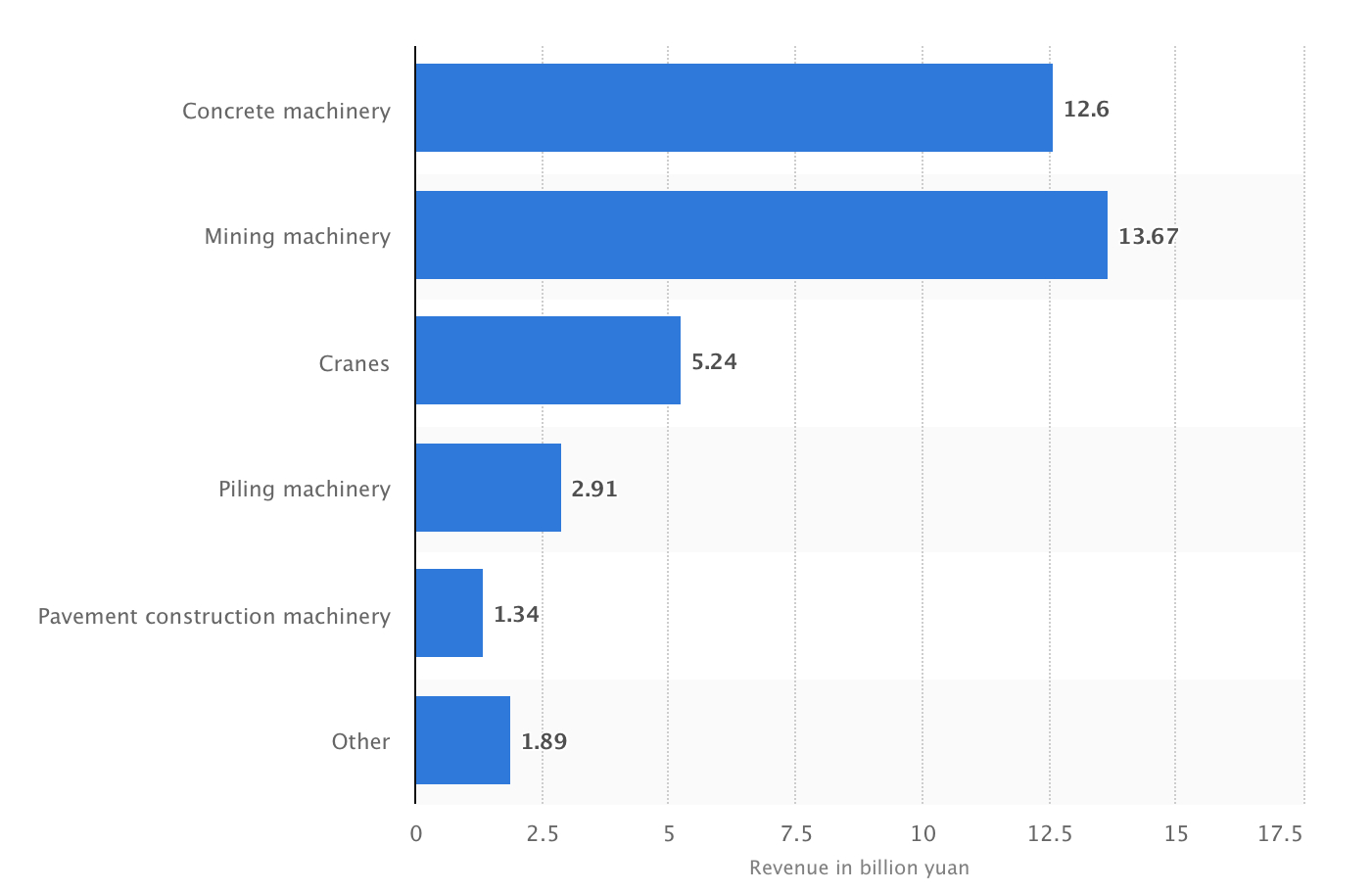

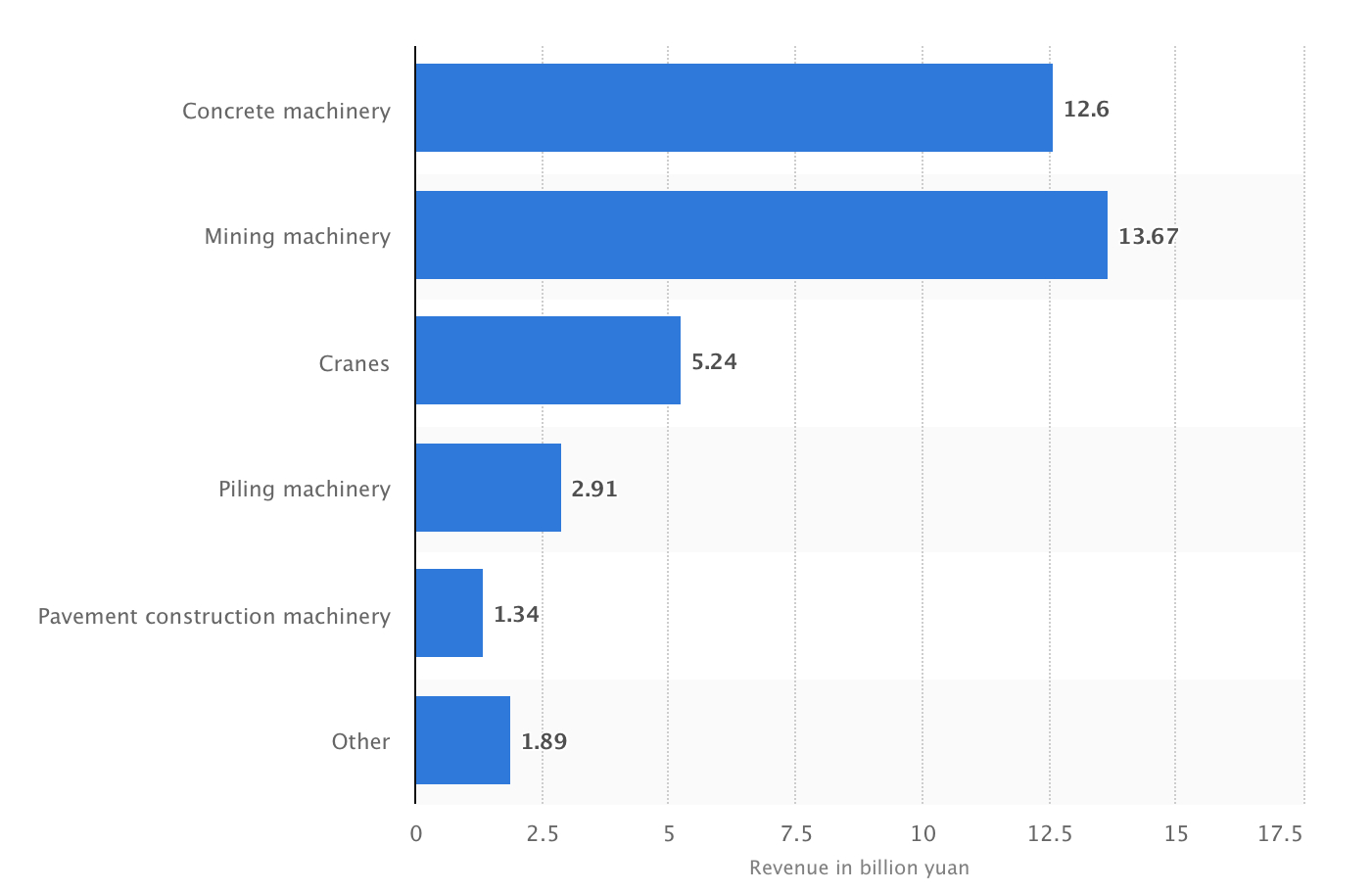

Revenue of SANY in China in 2017, by segment (in billion yuan)

CGTN Photo

Sany’s rise benefited from the hundreds of billions of dollars the government poured into the enormous infrastructure projects in 2008. But as the construction boom slows, it started to hunt for sales elsewhere and has moved beyond the country’s borders to cultivate markets in the US, Europe, Latin America, and India.

Its overseas sales increased by 25.1 percent year-on-year in 2017 to 11.62 billion yuan.

Helping fuel the growth of the overseas market, Liang said, is China’s Belt and Road Initiative.

“The Belt and Road Initiative is becoming a very important driver for Sany’s international development,” said Liang, “Sany has done a better job than its competitors in India, where the sales is predicted to reach three billion yuan this year. ”

As Sany strove to gain a foothold overseas, it has made a series of brash moves, and it has both grown and stumbled, especially in the US, Caterpillar’s home turf.

Its biggest hurdle starting off was finding experienced US dealers to sell and service the equipment, while the most seasoned ones have long been allied with Caterpillar and Japan’s Komatsu.

Sany also struggled with the view that Chinese products are of bad quality. It lacked the core skill or technology to make many of its components, which it buys from companies like Cummins and Bosch Rexroth.

Workers at a Sany facility in Changsha City, Hunan Province /CGTN Photo

But today Sany is narrowing the quality gap and winning customers in developed countries and among quality-conscious equipment buyers, including top mining companies.

As Sany has grown fast and generated economies of scale, it has ultimately allowed the company to invest vastly in R&D.

It spends five percent of its sales revenue on R&D, the highest in the industry, according to the company’s statement.

As of June this year, the company has applied for a total of 12,070 patents and authorized 8,751 items. The cumulative number of patent applications and authorizations has ranked first in the industry.

***

The is ripe for China Inc. for innovation now that they have accumulated enough capital and

expertise.

Caterpillar used to be the king of excavator. I don;t think they ever form joint venture with Sany So those accusation of stealing is misplaced.China become formidable competitor largely because of continuing investment in R&D ,modern production facility, and growing domestic market. Starting as welding rod company Sany mushroom into one of the biggest off road machinery

It achieve notoriety because

During the , a crane manufactured by SANY was used in rescuing the Chilean miners. A pump from the company was donated to the to assist with the emergency response to the .

In 2011, Sany signed several contracts to open new manufacturing centers, the most important of them include the and centers, and the fifth international equipment plant in , the latter with an investment of US$200 million

Sany eyes bigger slice of global heavy equipment market

By CGTN's Yan Qiong

2018-08-05 13:45 GMT+8

At a Sany facility in the city of Changsha city in central China’s Hunan Province, where an array of excavators, cranes, and concrete machinery is displayed, Liang Linhe, vice president of Sany Heavy Industry, told CGTN that “the forecasted revenue growth in 2018 is 50 percent, and by the end of this year, Sany will overtake Caterpillar in excavator sales for the first time.”

Liang Linhe, senior vice president of Sany Heavy Industry Co. /CGTN Photo

You may have never heard of Sany, one of China’s most important homegrown success stories, but the name is as big as Caterpillar in China, where it has rocketed from a company making welding materials in 1989 to becoming the biggest construction equipment manufacturer.

CGTN Photo

Revenue of SANY in China in 2017, by segment (in billion yuan)

CGTN Photo

Sany’s rise benefited from the hundreds of billions of dollars the government poured into the enormous infrastructure projects in 2008. But as the construction boom slows, it started to hunt for sales elsewhere and has moved beyond the country’s borders to cultivate markets in the US, Europe, Latin America, and India.

Its overseas sales increased by 25.1 percent year-on-year in 2017 to 11.62 billion yuan.

Helping fuel the growth of the overseas market, Liang said, is China’s Belt and Road Initiative.

“The Belt and Road Initiative is becoming a very important driver for Sany’s international development,” said Liang, “Sany has done a better job than its competitors in India, where the sales is predicted to reach three billion yuan this year. ”

As Sany strove to gain a foothold overseas, it has made a series of brash moves, and it has both grown and stumbled, especially in the US, Caterpillar’s home turf.

Its biggest hurdle starting off was finding experienced US dealers to sell and service the equipment, while the most seasoned ones have long been allied with Caterpillar and Japan’s Komatsu.

Sany also struggled with the view that Chinese products are of bad quality. It lacked the core skill or technology to make many of its components, which it buys from companies like Cummins and Bosch Rexroth.

Workers at a Sany facility in Changsha City, Hunan Province /CGTN Photo

But today Sany is narrowing the quality gap and winning customers in developed countries and among quality-conscious equipment buyers, including top mining companies.

As Sany has grown fast and generated economies of scale, it has ultimately allowed the company to invest vastly in R&D.

It spends five percent of its sales revenue on R&D, the highest in the industry, according to the company’s statement.

As of June this year, the company has applied for a total of 12,070 patents and authorized 8,751 items. The cumulative number of patent applications and authorizations has ranked first in the industry.

***

The is ripe for China Inc. for innovation now that they have accumulated enough capital and

expertise.

Last edited: