If Nikon can do it then in the future SMEE 28nm DUVL can, with the reports from my previous post of China Academy of Science had developed a 5nm laser lithography maybe they had plans and will work with SMEE to implement it in its future variants. I think SMEE or CETC may do a dual approach with its EUVL program and improving its DUVL. I'm speculating and forgive me for being an over enthusiast but a 5nm 3D DUVL chiplet will be competitive with the latest TSMC 3NM EUVL chip and if SMEE can improve the performance level comparable to NIKON and ASML NXT 2050i then it can buy some time for China IC especially Huawei, before the Chinese EUVL can be delivered in 2025.

From my friend

@Oldschool

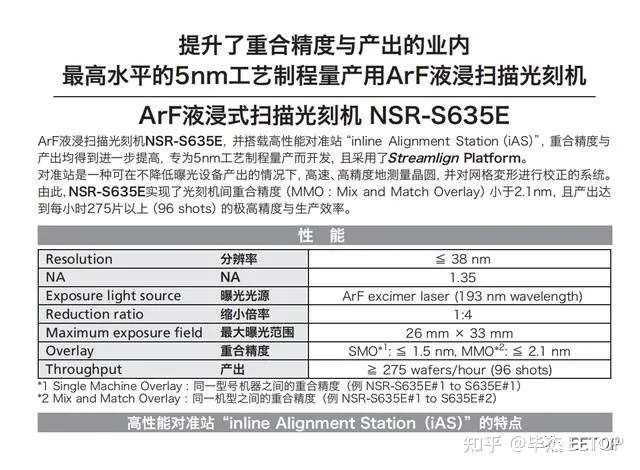

Nikon new immersion lithography can make 5nm, schedule to be on sale 2023.

Japan may not sell to CHina but this indicates DUV immersion can go beyond 7nm and down to 5nm.

It can also process 5 nanometers! If you can't buy EUV, you can consider Nikon's new generation of ArF immersion lithography machine

2021-10-24 13:06:36 Source: EETOP

Nikon recently announced that it is currently developing the next-generation NSR-S636E ArF immersion lithography machine, which will provide excellent stacking accuracy and ultra-high throughput to support the manufacturing of the most critical

equipment. Product sales are planned to start in 2023.

With the acceleration of digital transformation (DX), there is an urgent need to process and communicate large amounts of data very quickly. In order to meet these requirements, high-performance

imperative, and

device technology is constantly evolving. At the same time, attention is paid to the miniaturization of circuit patterns and the development of 3D device structures.

NSR-S636E-line alignment station having enhanced (iAS), which is integrated between the coater / developer unit and a lithography scanner

pre-

module. S636E and iAS utilize complex multi-point alignment

and advanced correction functions to enable equipment manufacturers to achieve the strict overlay accuracy required for 3D equipment structures while maximizing the productivity of immersion lithography machines. NSR-S636E is very suitable for cutting-edge

manufacturing, including logic and storage devices, CMOS image sensor applications, etc.

More about the NSR-S636E parameters have not been announced, but from the previous generation S635E claims may have been produced 5nm

of view, S636E should at least be a more efficient way of producing 5 nanometer

, and our country can not buy this for

For the lithography machine, it is a good choice.