Medical robot maker aims to break into European market

By MA SI | CHINA DAILY | Updated: 2022-10-10 06:59

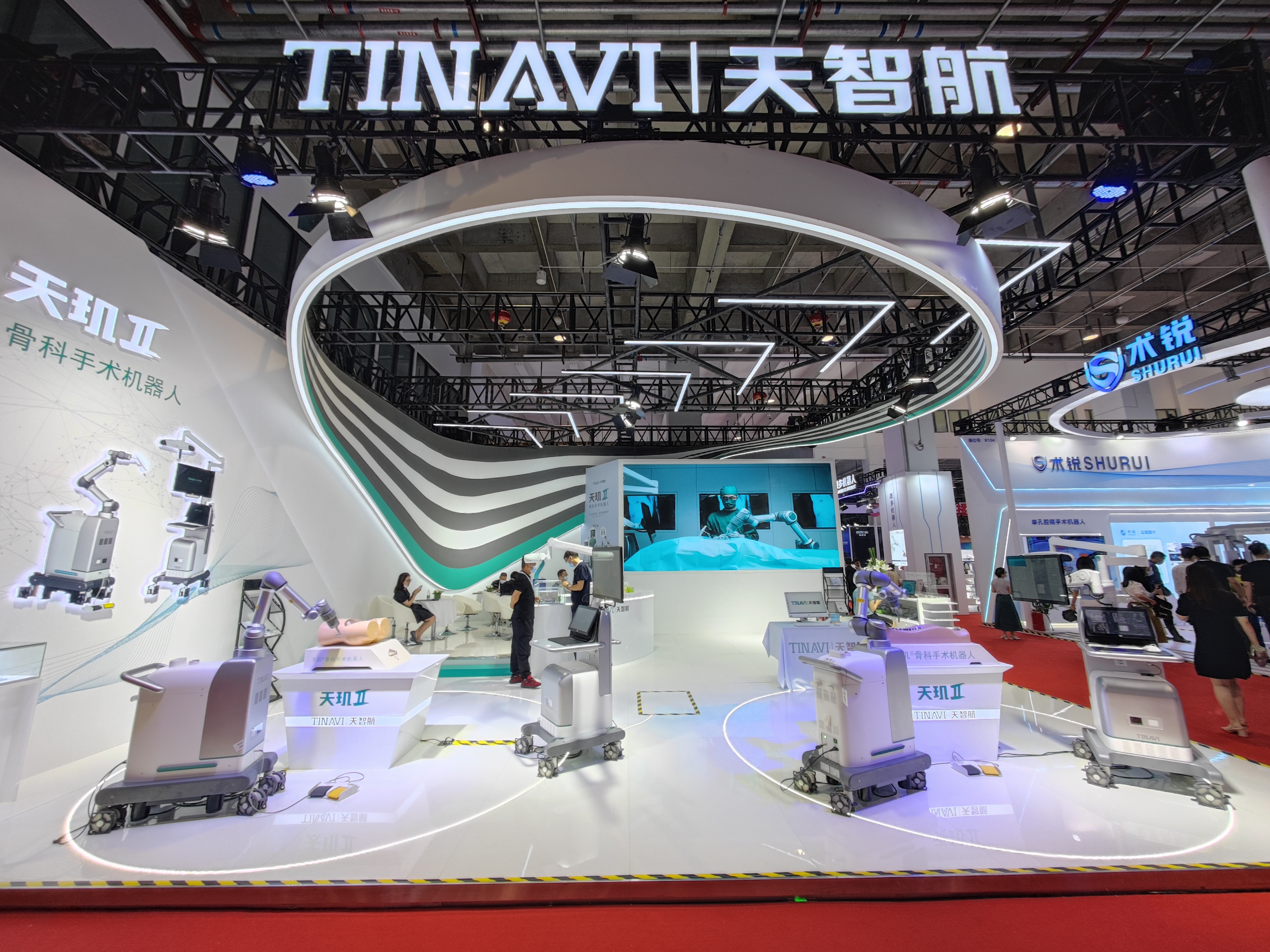

High-tech medical robots are displayed at Tinavi's booth during the 2022 World Robot Conference held in Beijing in August. [PHOTO/CHINA DAILY]

With CSA certificate, tech pioneer pushes to apply for EU sales license

Tinavi Medical Technologies Co Ltd, a Chinese pioneer in medical robots, is applying for the CE marking in Europe as part of its broader push to break into overseas markets.

The CE marking is an abbreviation of the French phrase "Conformite Europeenne", which translates as "European Conformity". It is a conformity mark used to monitor and regulate goods sold within the European Union.

Ma Min, president of Tinavi, said: "We are in the middle and late stages of applying for the CE marking, and we hope to get approved for the EU sales license in the near future."

The move marks big progress for Tinavi, which has brought China's first homegrown orthopedic surgical robot to the market. By the end of last year, the company's orthopedic surgical robots had been used in more than 20,000 orthopedic surgeries in China.

In December, Tinavi's TiRobot II, a robotics-guided orthopedic surgical system, obtained the Canadian Standards Association (CSA) certificate, which the company said made it the first orthopedic surgical robot from China with technology qualified for entry into the North American market.

The CSA is a not-for-profit membership-based association headquartered in Toronto. It develops consensus standards to help protect the health and safety of Canadians and is also recognized around the world.

The robotics-guided orthopedic surgical system is applied in trauma surgery on the cervical spine, thorax, lumbar area, sacrum, pelvis and limbs. It was certified under the latest industry standards, including product safety regulations, medical software, availability and specialized robot performance standards, the company said.

"The surgical robot's complexity is an aggregation of many modern high-tech elements," said Ge Yanqing, vice-president of the Canadian Standards Association Group. "The surgical robot is more technologically sophisticated and precise, with higher added value, than other robots. In China, surgical robots have been applied to orthopedics, neurosurgery, cardiology, gynecology and other operations."

Xu Jin, CEO of Tinavi, said it is well known that medical standards and requirements in North America are among the strictest in the world. "Therefore, the CSA Group certificate is a recognition of the company's techniques and quality, and may pave the way for Tinavi to obtain necessary approvals to enter the international market," Xu said.

Huang Junhui, secretary of the board of directors at Tinavi, said the CSA certification is equivalent to a prerequisite for applying to the United States Food and Drug Administration (FDA).

"The CSA is a certification body recognized by the FDA. After this certification, we have the qualifications to apply to the FDA."

Tinavi, founded in 2006, holds over 100 patents, the company said. It was listed on the Science and Technology Innovation Board of the Shanghai Stock Exchange in July 2020 and became the first listed medical robot enterprise in China, raising about 448 million yuan ($61.8 million).

This year, a new integrated surgical treatment called Viper Prime& TiRobot was launched in the market. This new product was jointly developed by US healthcare giant Johnson & Johnson and Tinavi, and it has integrated TiRobot and Viper Prime, an advanced, minimally invasive implant system of Johnson & Johnson. The companies said it provides surgeons with efficient and intelligent services and will benefit more patients with spinal problems.

The move marked the latest step in cooperation between Johnson &Johnson and Tinavi. In October 2019, the two sides signed an agreement on business and research cooperation.

Tian Wei, an academician at the Chinese Academy of Sciences, said traditional bone surgeries typically demand a high degree of steady surgical experience, as well as high precision and a clear view of the injuries. In such cases, the need for deep incisions and exposure to multiple X-rays may elevate medical risks.

Robots can apply minimally invasive orthopedic solutions to these difficulties, Tian said.

Tian conducted the world's first robot-assisted surgery on the upper cervical vertebrae in 2015 by using Tinavi's robots. Back then, Tian was the president of Beijing Jishuitan Hospital.

He said, it is notable that midsized hospitals in China are more eager to buy orthopedic surgery robots than large hospitals.

"In the past, midsized hospitals did not dare to perform very sophisticated operations, and they would recommend patients to transfer to larger hospitals. But now, surgical robots can provide a great deal of assistance in carrying out such surgeries," Tian said.