OFILM releases a new generation of short-range millimeter-wave radar to empower autonomous driving

Release time: 2020-11-26Recently, after the technical breakthrough of the smart car R&D team, OFILM's new generation of short-range millimeter-wave radar was officially released, leading the industry in low-speed and short-range performance.

▲ OFILM short-range millimeter-wave radar module

Industry-leading low-speed and short-distance performance

OFILM's new generation of short-range millimeter-wave radar breaks through the functional limitations of traditional radars, and opens a new era of low-speed short-range radar with industry-leading performance.

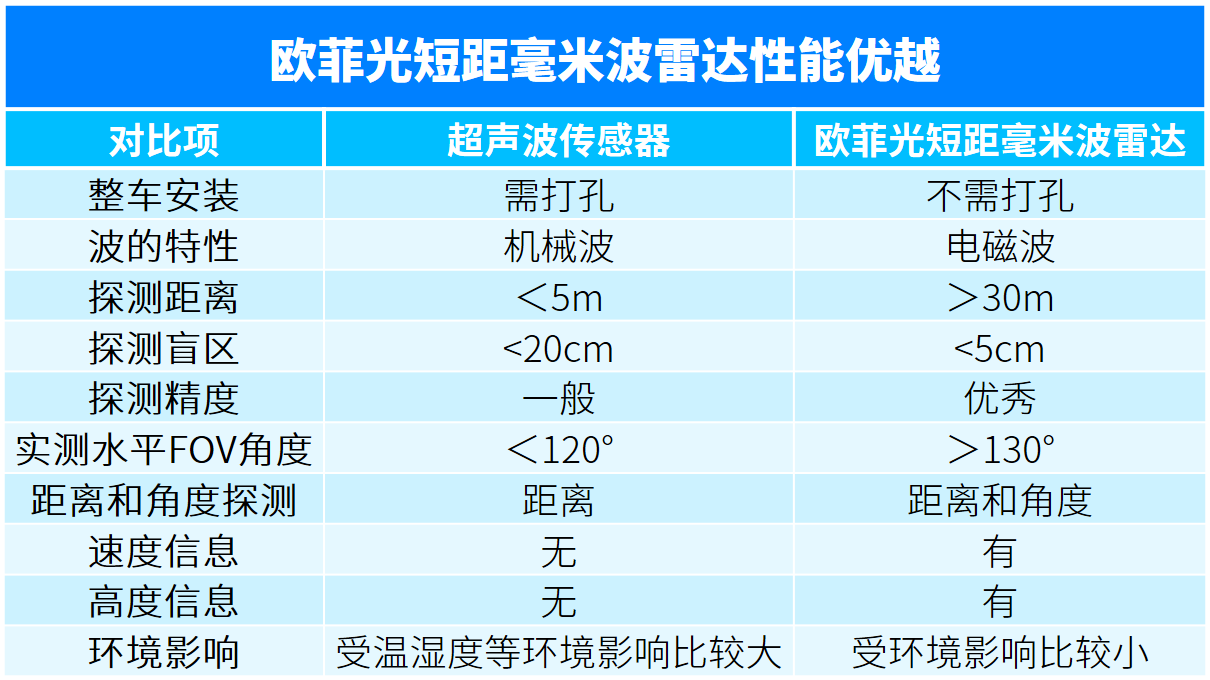

At present, the low-speed radar sensor configuration in the smart car market is dominated by ultrasonic radar. However, ultrasonic radar has obvious shortcomings in application. Its accuracy is low, the detection distance is short, more accurate information cannot be obtained at high speed, and it is easily affected by surface contamination, raindrops, ice and snow, etc., so that the sensor cannot fully perform its functions. In contrast, OFILM's short-range millimeter-wave radar is comparable in cost to ultrasonic radar, but its low-speed and short-range performance is much higher than that of ultrasonic radar, leading the industry.

▲ Compared with ultrasonic radar, OFILM short-range millimeter-wave radar has superior performance

On the basis of traditional functions such as BSD, LCA, DOW, and RCTA, OFILM short-distance millimeter-wave radar can realize near-field and low-speed detection, and its various indicators are at the leading level in the industry: it surpasses ultrasonic sensors in terms of detection range, speed, angle, etc. Realize that the car can accurately judge the surrounding environment and reduce collisions and other situations; it has a leapfrog performance improvement for MEB (emergency braking) at low speeds, and can adapt to more scenarios; the overall price is close to that of ultrasonic radar, reaching the balance between performance and price perfect combination.

OFILM: At present, Xinfei New Materials has mass-produced 0.3mm VC vapor chamber, and is developing 0.22mm

Every AI newsletter, some investors ask on the investor interaction platform: How thin can the vapor chamber be the thinnest?

OFILM (002456.SZ) stated on the investor interaction platform on November 29 that the company's main business products include optical imaging modules, optical lenses, microelectronics and smart car related products. Focusing on the core series of products such as smart phones, smart cars, and new fields, the company has formed a product structure with rich types, complete series, reasonable distribution, and comprehensive technical paths, leading the innovation and upgrading of a full range of products. Jiangxi Xinfei New Materials Co., Ltd., which the company holds shares in, actively develops a variety of new materials such as semiconductor lead frames, and develops the market for film materials and semiconductor metal materials. At present, Xinfei New Materials has mass-produced 0.3mm VC vapor chamber, and is developing 0.22mm.