by78

General

Am I reading this right? Does this mean CJ-2000 is a ? If so, this is the first I've heard of it, or am I hopelessly uninformed about the project?

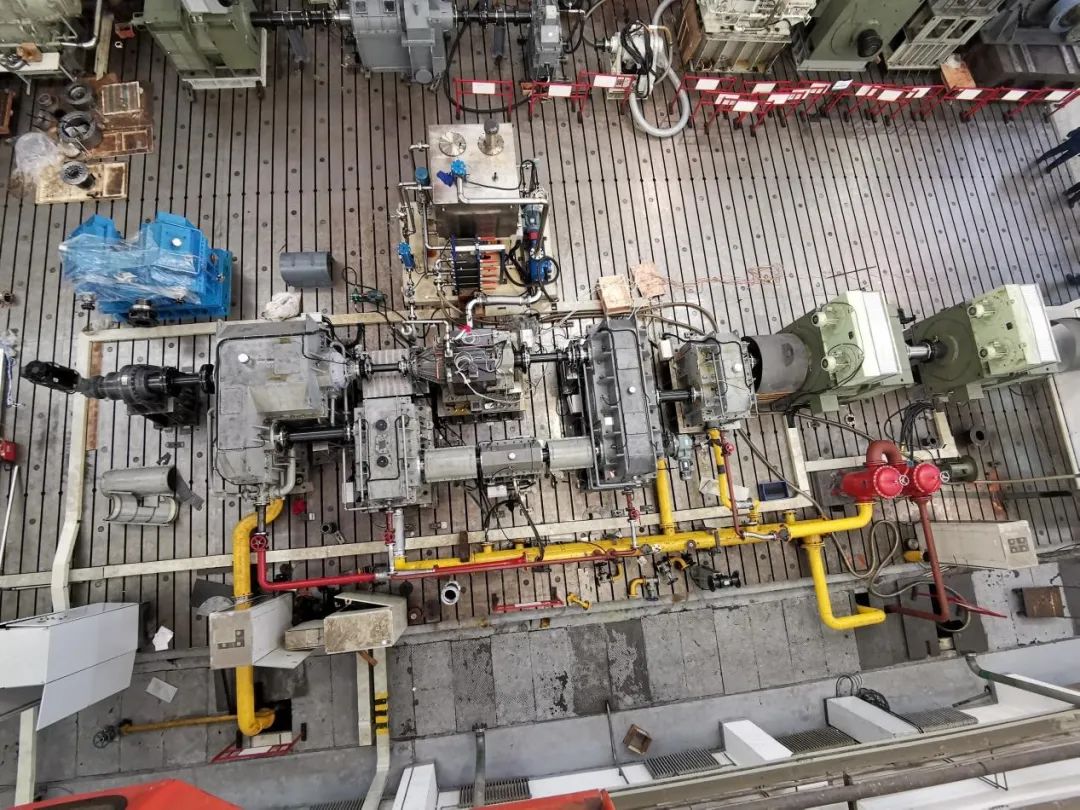

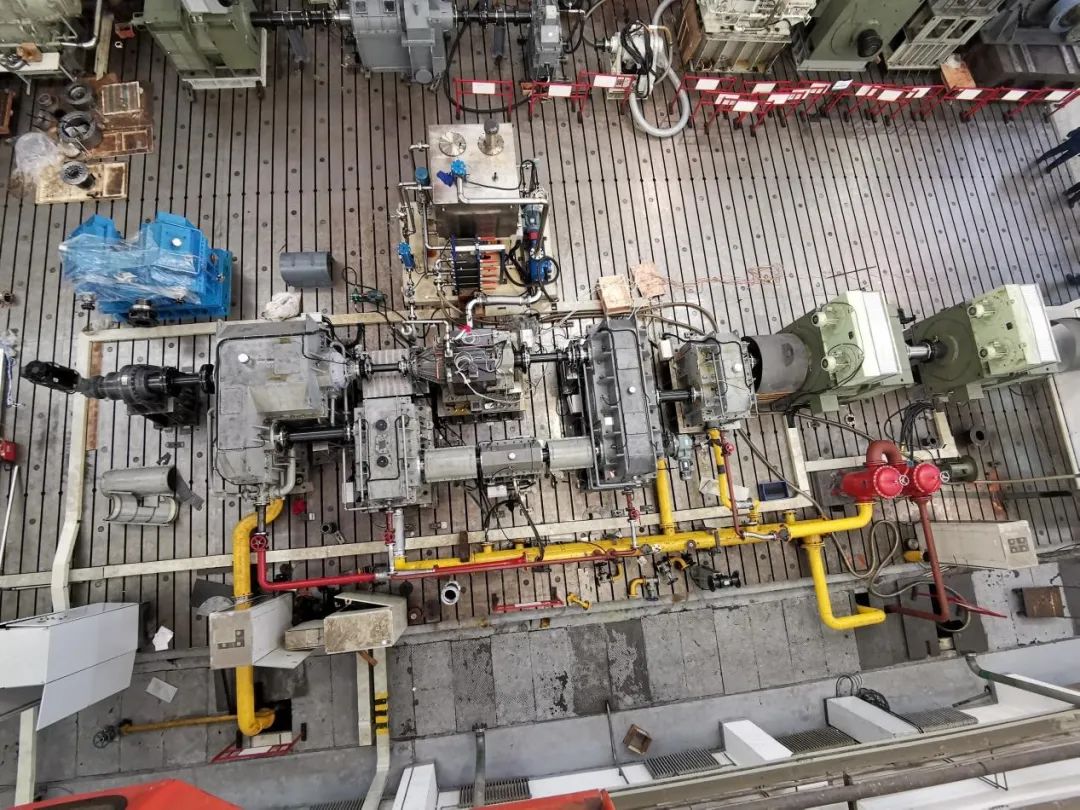

近日,哈尔滨广瀚传动有限公司承担的中国商用发动机CJ2000项目的国产首台风扇驱动齿轮箱试验任务顺利完成。

风扇驱动齿轮箱具有传递功率大(20MW)、工作转速高(9000rpm)、功率密度高的特点,是新一代航空发动机动力系统的重要设备。自承接任务以来,公司领导科学规划、积极部署,成立专项团队,仅在一周之内就确定了机械功率封闭系统的加载器方案,并统筹推进,一次性获得成功,获得了用户的高度认可。

回顾项目执行的全过程,项目团队成员收获颇丰。一是创新是技术发展的内在动力。20MW机械功率封闭试验台,首次使用了无极变速的加载方式,突破了现有加载器的应用极限,有力的保证了项目的顺利完成。二是不断拓宽知识领域。丰富学识,提高技术水平,为创新的提升而不断积累。三是提振团队勇于创新的决心和信心。新技术领域取得突破,创新成果得到应用,这对研发人员至关重要,随着更多新技术的应用,公司的创新能力必将迈向新的台阶。

Harbin Guanghan Transmission Co., Ltd. successfully completed the test task of fan-driven gearbox for large aircraft

Recently, Harbin Guanghan Transmission Co., Ltd. successfully completed the test task of the first domestically produced fan drive gearbox for the Chinese commercial engine CJ2000 project.

The fan drive gearbox has the characteristics of large transmission power (20MW), high operating speed (9000rpm), and high power density. It is an important equipment for the new generation of aero-engine power system. Since taking over the task, the company's leaders have scientifically planned, actively deployed, and established a special team. Within only one week, they have determined the loader plan for the mechanical power closed system, and made overall plans to achieve success at one time, which has been highly recognized by users.

Reviewing the whole process of project implementation, the project team members have gained a lot. First, innovation is the internal driving force of technological development. The 20MW mechanical power closed test bench uses the infinitely variable speed loading method for the first time, which breaks through the application limit of the existing loader and effectively guarantees the smooth completion of the project. The second is to continuously broaden the field of knowledge. Enrich knowledge, improve technical level, and continuously accumulate for the improvement of innovation. The third is to boost the determination and confidence of the team to be brave in innovation. It is very important for R&D personnel to make breakthroughs in the field of new technologies and apply innovative achievements. With the application of more new technologies, the company's innovation ability will surely reach a new level.

Last edited: