You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese Engine Development

- Thread starter jackbh

- Start date

by78

General

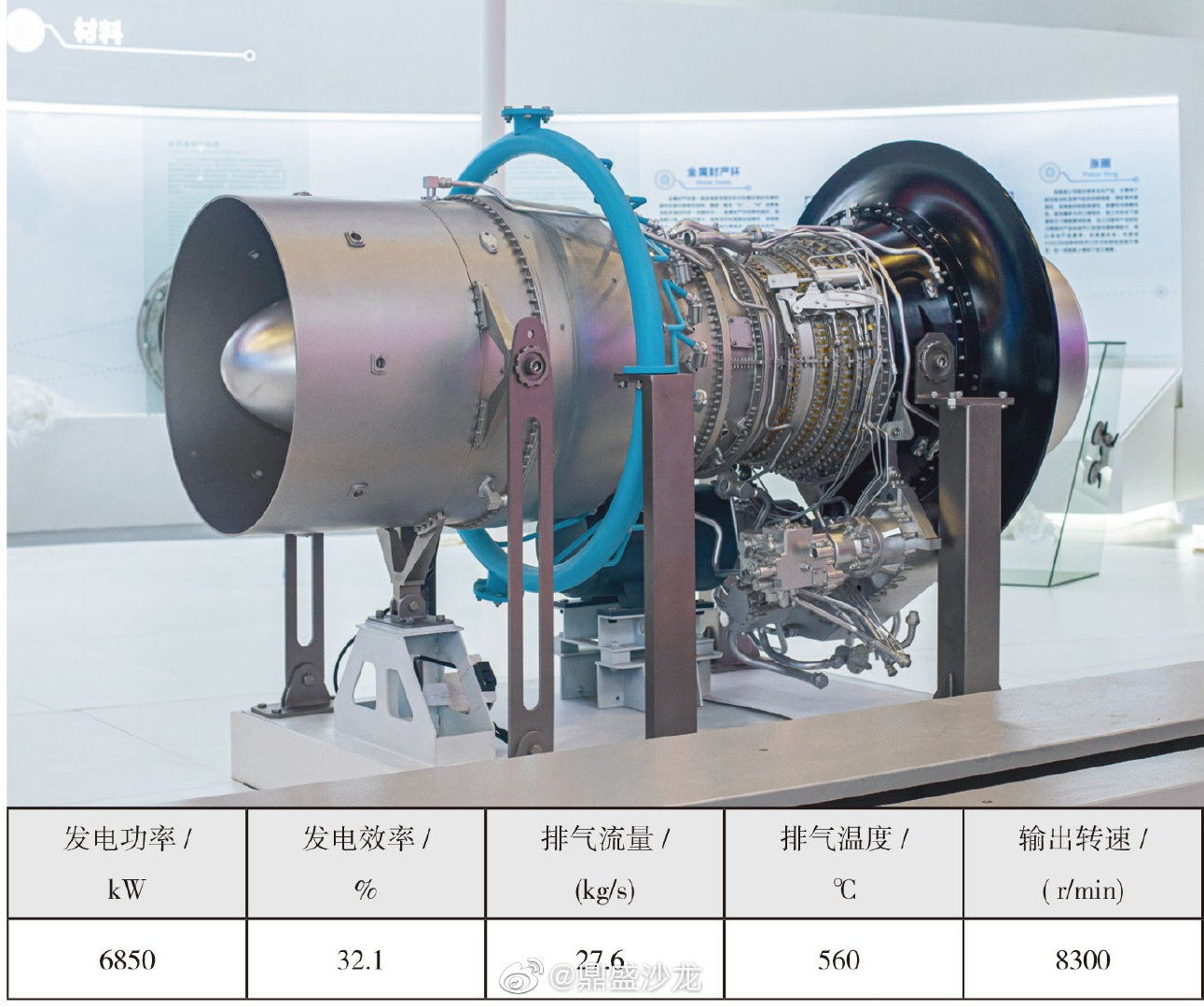

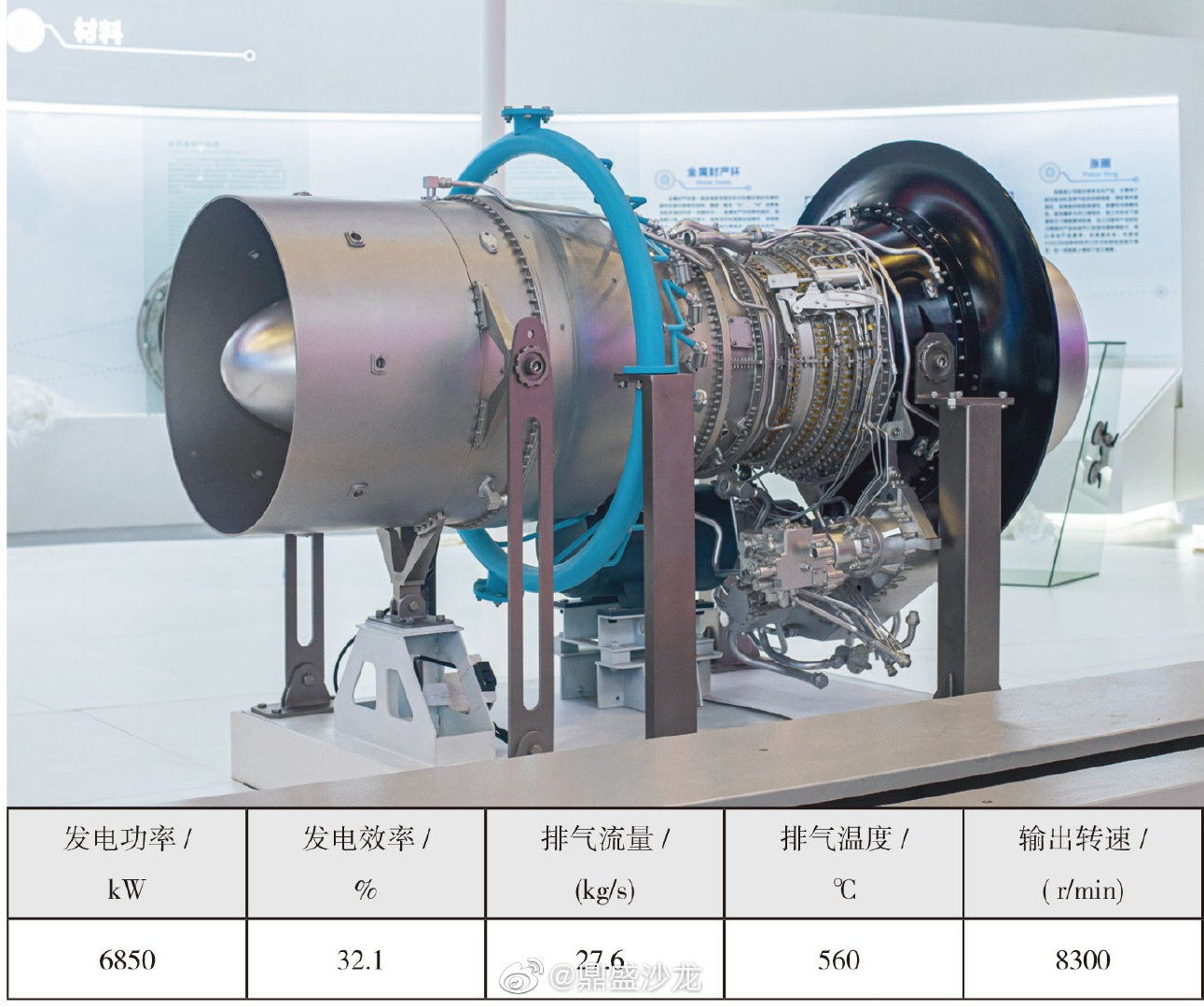

The AGT-7 gas turbine is a 7MW-class gas turbine derived from WS-10 Taihang. Suitable for marine propulsion. Civilian applications include power generation for offshore oil and gas platforms, backup power generation, etc.

Some specs:

– Power: 6850kW

– Generator efficiency: 32.1%

– Exhaust flow rate: 27.6kg/s

– Exhaust temperature: 560°C

– Output rotational speed: 8300rpm

Some specs:

– Power: 6850kW

– Generator efficiency: 32.1%

– Exhaust flow rate: 27.6kg/s

– Exhaust temperature: 560°C

– Output rotational speed: 8300rpm

China still lags behind in advanced forging technology for jet engine components

View attachment 81123

View attachment 81124

View attachment 81125

You can’t get fat by cramming one hundred dumplings into your mouth. One step at a time.

You can’t get fat by cramming one hundred dumplings into your mouth. One step at a time.

The point is when we talk about jet engines,everyone immediately jump into materials. But jet engine is a lot more than just materials, the processing technic is also an important factor.

Some info in this report are outdated. China has the largest and strongest hydrualic press () in the world.China still lags behind in advanced forging technology for jet engine components

View attachment 81123

View attachment 81124

View attachment 81125

According to this , China completed building three large presses in 2012 alone - a 80K, a 40k and a 30K:

而我国自打1973年投产第1台30000吨级的模锻压机后,停滞了将近40年,直到2010年前后爆发式地研制了多台大型压机,仅2012年建成的就有30000吨(昆仑重工)、40000吨(三角航空)、80000吨(德阳二重)模锻压机各一台。

On 精密碾轧技术 (precision rolling for aero-engines? not sure about the translation), AVIC (中航工业) made the in 2014:

Google translation (emphasis mine):突破了难变形材料异型环件精确辗轧的异型环坯料设计与制备、径-轴双向轧制、数值模拟等多项关键技术,成功实现了高温合金、钛合金等难变形材料的复杂截面环形件的精确辗轧成形,材料利用率提高到了20%以上,精度提高到5‰以内,满足了我国航空发动机关键、重要部件的自主保障。发动机环形件的精确碾轧技术具有工艺过程控制合理、材料利用率高、锻件组织致密、锻件流线完整等优势,适应航空发动机高性能、低成本、长寿命和短周期研制的发展需要,提高了我国环件精确碾轧成型领域的自主创新能力。

"It has broken through a number of key technologies such as the design and preparation of shaped ring blanks, radial-axis bidirectional rolling, and numerical simulation for precise rolling of shaped rings of difficult-to-deform materials, and has successfully realized the complex cross-section annular shape of difficult-to-deform materials such as superalloys and titanium alloys. Through the precise rolling and forming of parts, the material utilization rate has been increased to more than 20%, and the accuracy has been increased to within 5‰, which meets the independent guarantee of key and important components of my country's aero-engines. The precise rolling technology of engine ring parts has the advantages of reasonable process control, high material utilization rate, dense forging structure, and complete forging streamline. It meets the development needs of high performance, low cost, long life and short cycle development of aero-engine The independent innovation ability in the field of precise rolling and forming of ring parts in my country."

This is an from Jun 2021 about 航宇科技 the company listed in the footnote of the report (emphasis mine):

航宇科技是一家专门从事先进锻压技术应用研究与工程化应用研究的民营股份制企业,目前,已成为亚太地区唯一能为GE航空提供商用发动机高温合金高压涡轮机匣环形锻件的企业,也是亚太地区唯一具备全球六大商用航空发动机公司合格供方资质的锻件制造企业,产品销往美国、英国、韩国、意大利、瑞典等国家。其研发的700吨轧制力4500毫米精密近轴双向碾环机技术,在行业里全国排名第一、世界排名第二;在国内外,航宇科技首次解决了航空发动机用机匣整体轧制技术和薄壁异形环件超临界轧制的技术难题,并获得4项国家发明专利……

2018年,航宇科技的‘718Plus合金的锻件成形方法’发明专利荣获中国专利优秀奖。该专利解决了目前环锻件在制造过程中易开裂等技术难题,目前已应用于航空航天、燃气轮机、核电、船舶、离心机等领域内异形环件制造。

Not every element of engine manufacturing, or every component has the same impact on performance and capability. Some processing techniques specifically matter more for the economics of running an engine business than for the quality of your engine. Some processing techniques aren’t as essential for the components that use them, and there are alternative material and processing options. Most parts that can be made with forging in particular are often replaceable with other techniques like 3D printing, or are moving to materials that require other techniques like CMCs.The point is when we talk about jet engines,everyone immediately jump into materials. But jet engine is a lot more than just materials, the processing technic is also an important factor.

Some info in this report are outdated. China has the largest and strongest hydrualic press () in the world.

I don't think it's outdated, the info is extracted from this report

which was published in 2021/06/29. So it is pretty up to date.

You do realize that not all factories in China(or any country for that matter)are equal right?There is advanced smart factory,there is also backward small factory,you have to look at the average level of factories in that country. It is actually mentioned in the report

Not every element of engine manufacturing, or every component has the same impact on performance and capability. Some processing techniques specifically matter more for the economics of running an engine business than for the quality of your engine. Some processing techniques aren’t as essential for the components that use them, and there are alternative material and processing options. Most parts that can be made with forging in particular are often replaceable with other techniques like 3D printing, or are moving to materials that require other techniques like CMCs.

Aerospace components forging isn't your regular forging