I read that China ordered a few Be-200s, have they been delivered?Russia has enough issues manufacturing Be-200s for itself given the lack of availability of the Ukrainian Progress D-436TP engine it uses.

It is supposed to be replaced with a variant of the PD-8 engine. But the PD-8 will only enter service in 2 years at best. It remains to be seen when a variant for the Be-200 will be made after that. The PD-8 engine will further need to be modified to be more resistant to salt water.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Chinese Aviation Industry

- Thread starter FriedRiceNSpice

- Start date

SMH. There is no local substitute for CATIA. If sanctioned, search for a crack, I suppose.

CATIA and Solidworks are probably major ones but I'm sure there are some aviation specific software like the solidworks of aviation if it is for structural analysis and simulations then probably more specialised software and not just CATIA. I honestly think Dassault's magnum opus is CATIA followed by Solidworks... even after considering some great aircraft in their repertoire.

American aviation giants - Boeing, Northrup Grumman, and LM all use these. In fact these are the CAD mainstays of global aviation engineers for the last nearly half century.

Still no one new ARJ21 flew since 29 Dec 2021?! And no any more deliveries since 28 Dec 2021? After 24 new ARJ21s flew in 2021 and 22 delivered... Surpisingly...

delete

Theres 100% definitely more cracked/pirated versions of Solidworks and Matlab and stuff like that than legit versions on US university campuses. I can't imagine any of China's aerospace companies slowing down for a second if suddenly they can't use those software.SMH. There is no local substitute for CATIA. If sanctioned, search for a crack, I suppose.

broadsword

Brigadier

Theres 100% definitely more cracked/pirated versions of Solidworks and Matlab and stuff like that than legit versions on US university campuses. I can't imagine any of China's aerospace companies slowing down for a second if suddenly they can't use those software.

Agreed. But China should have been using its own CADCAM software by now. There is a lot of graduate talent, I'm sure.

by78

General

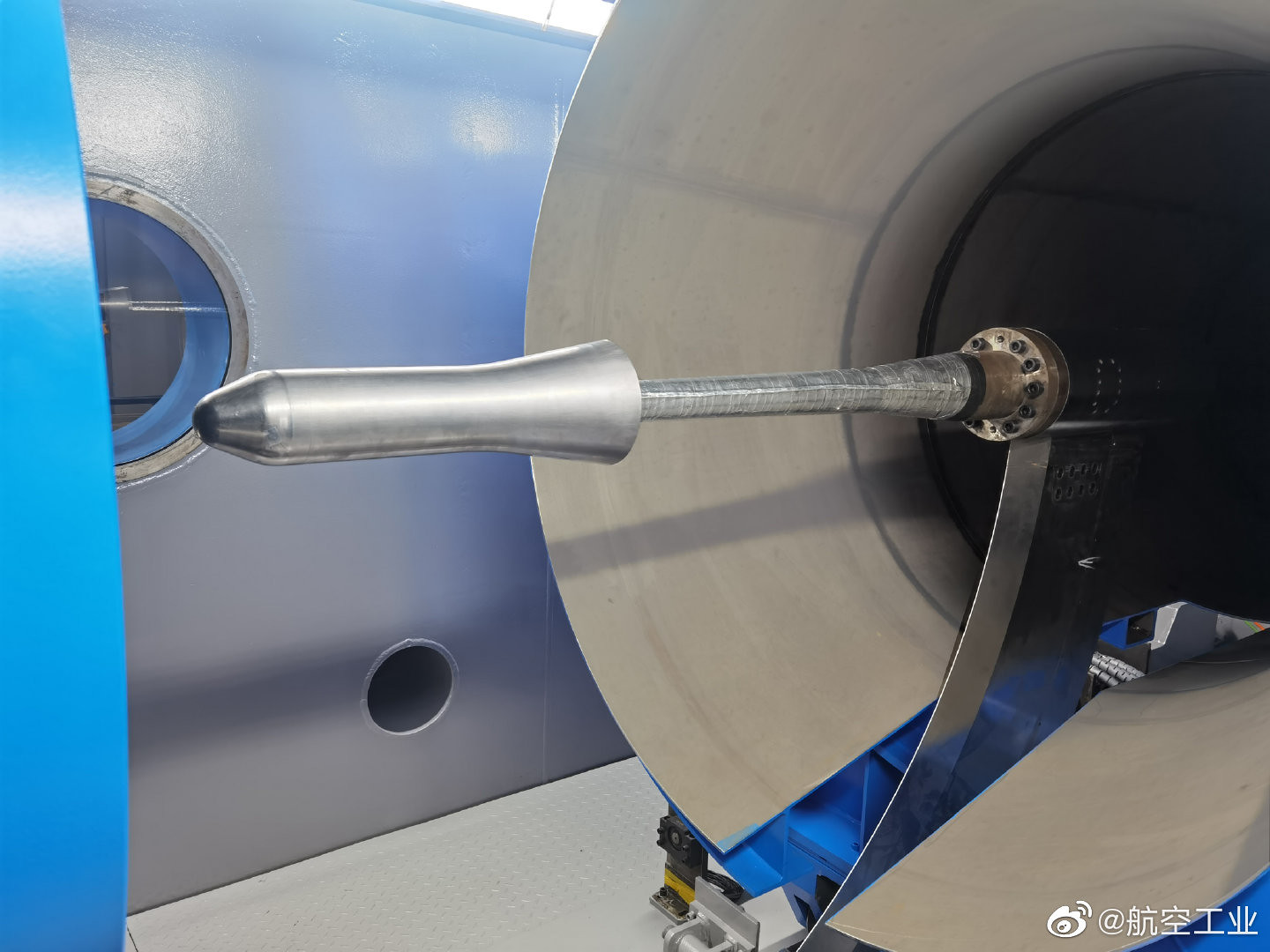

The FL-64 hypersonic wind tunnel has successfully completed the main Mach number flow field calibration, marking the completion of the first stage of the commissioning process.

An update on the FL-64 hypersonic wind tunnel. The original text is below, followed by a Google translation.

中国航空报讯:近日,航空工业气动院在FL-64风洞完成典型模型三维纹影试验技术验证,成功实现高超声速构型的激波系三维重构。

本试验以风洞现有滚转机构和二维纹影系统为基础,采用断层扫描技术原理,通过模型滚转获得全方向纹影图像,经过正弦图抽取、拉东逆变换、断层数据拼接等图像和数据处理,成功构筑具备像素级分辨率的空间光强场,可用于显示三维激波结构。三维纹影测试技术的建立对促进高超声速三维流动机理研究,提升风洞试验数据品质具有重要意义。

FL-64风洞持续开展流场校测与标模试验,目前已具备马赫数4.0~8.0全马赫试验能力。与此同时,FL-64风洞不断加强特种试验能力建设,先后完成低动压、进气道、流动显示、CTS等多项试验能力的验证。随着试验系统和测量技术的不断扩展提升,FL-64风洞试验技术能力日趋完善。项目团队将以风洞为依托,充分发挥气动院各综合科研团队技术优势,坚持“创造高产出价值,取得原创性成果”的工作目标,不断提升高超声速风洞试验与科研技术水平。(辛亚楠 赵荣奂 郑佳丽)

The FL-64 wind tunnel of the Aeronautical Institute of Aeronautics and Astronautics has completed the first domestic hypersonic 3D Schlieren test

Recently, the Aerodynamics Institute of the Aviation Industry completed the technical verification of the 3D schlieren test of a standard model in the FL-64 wind tunnel, and successfully realized the 3D reconstruction of the shock wave system in the hypersonic configuration.

This experiment is based on the existing rolling mechanism and two-dimensional schlieren system of the wind tunnel, adopts the principle of tomography technology, and obtains omnidirectional schlieren images through model rolling. Image and data processing, successfully constructed a spatial light intensity field with pixel-level resolution, which can be used to display the three-dimensional shock structure. The establishment of 3D schlieren testing technology is of great significance for promoting the study of hypersonic 3D flow mechanism and improving the quality of wind tunnel test data.

The FL-64 wind tunnel continues to carry out flow field calibration and standard model tests, and currently has the full Mach test capability of Mach 4.0 to 8.0. At the same time, the FL-64 wind tunnel has continuously strengthened the construction of special test capabilities, and has successively completed the verification of many test capabilities such as low dynamic pressure, air intake, flow display, and CTS. With the continuous expansion and improvement of the test system and measurement technology, the technical capabilities of the FL-64 wind tunnel are becoming more and more perfect. Relying on the wind tunnel, the project team will give full play to the technical advantages of the comprehensive scientific research teams of the Pneumatic Institute, adhere to the work goal of "creating high output value and achieve original results", and continuously improve the level of hypersonic wind tunnel testing and scientific research technology. (Xin Yanan, Zhao Ronghuan, Zheng Jiali)