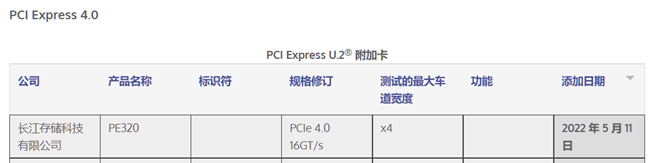

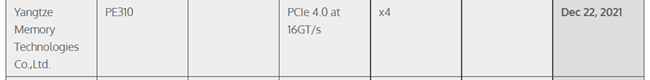

YMTC's self-developed SSD controllers have been certified by PCI-SIG PCI-E, all with PCIe 4.0 x4 interface

According to micronet news, recently, according to a report from tomshardware, YMTC is designing its own SSD controller. Recently, two of the controllers were validated for PCI Express compliance at the PCI-SIG workshop.

According to the data, YMTC's PCI-SIG-validated SSD controller series currently includes models PE310 and PE320, but there may be other controllers that are not listed in the PCI-SIG integrator list.

Both the PE310 and PE320 feature a PCIe 4.0 x4 host interface, designed for high-end drives, and may respectively support different numbers of NAND flash channels, the report said.

It is reported that the new generation of 3D NAND memory requires advanced error correction and signal processing algorithms. Therefore, since 2000, major NAND manufacturers have begun to develop SSD master control by themselves, instead of leaving it to a third party to ensure better product quality.

Historically, among manufacturers of 2D and 3D NAND, only Samsung and Intel have designed SSD controllers in-house, while other leading flash manufacturers have left SSD controller development to third parties. In many cases, a poor combination of NAND, controller, and firmware results in a poor-quality drive.