On October 31, the "Aeronautical Ultra-High-Speed Impact Hydroforming Technology and Equipment" undertaken by the Plastic Processing Advanced Technology Team of the Institute of Metal Research, Chinese Academy of Sciences passed the appraisal of scientific and technological achievements organized by the Chinese Society of Mechanical Engineering.

Liu Gang, deputy director of the Institute of Metals, attended the appraisal meeting and delivered a speech. Professor Wan Min from Beijing University of Aeronautics and Astronautics served as the leader of the review expert group. Researcher Zhang Shihong, researcher Xu Yong and other major researchers reported the development of the project to the expert group and answered questions from experts.

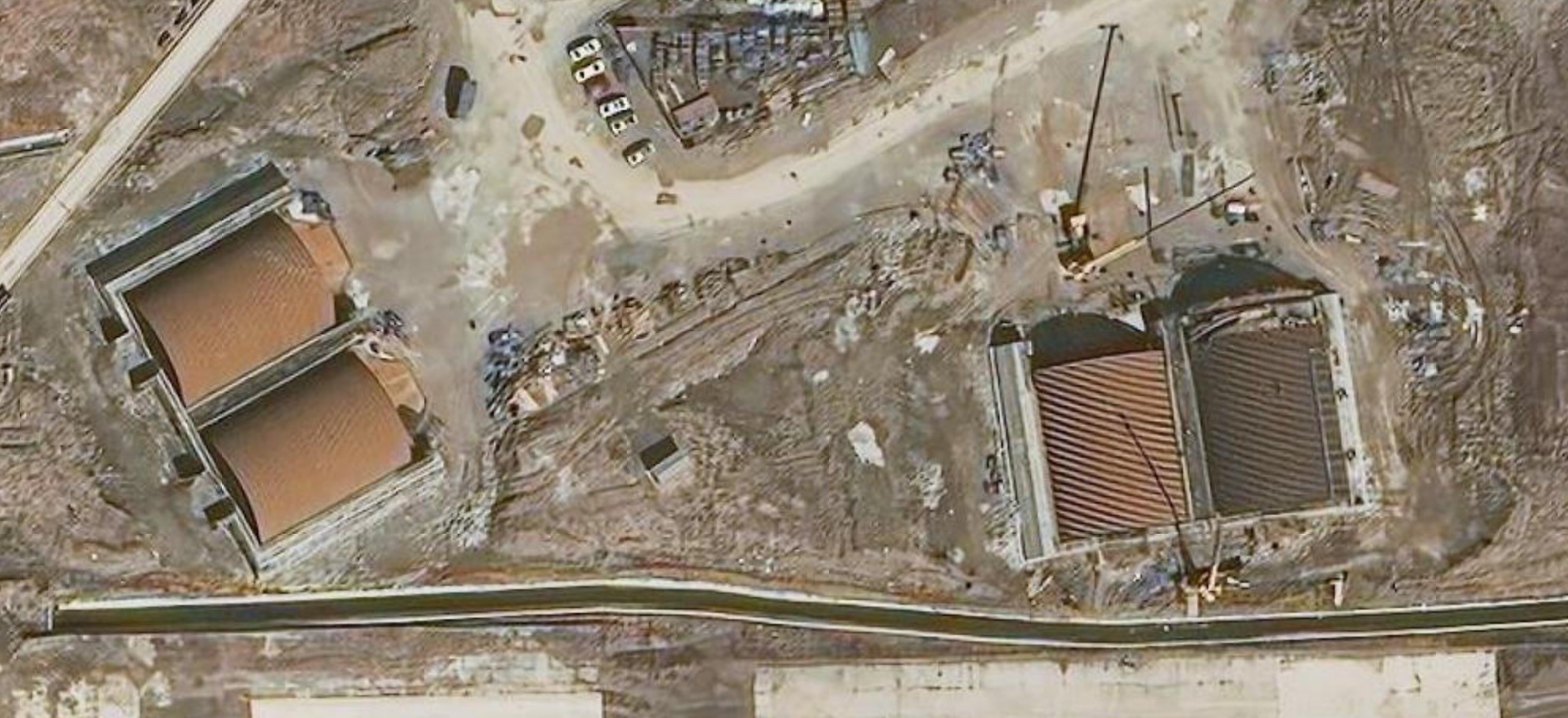

Based on the material characteristics of high strain rate plasticization, this project proposes a new aviation sheet metal parts manufacturing technology, realizes the organic combination of hydroforming and impact forming, overcomes the high-pressure energy storage combination device, the new "rod + hammer "Drive structure design, dynamic drag reduction design and other key structural designs have realized the output and precise control of high-speed and high-energy impact sources, successfully developed new ultra-high-speed impact hydroforming special equipment, and developed corresponding advanced forming technologies and products.

The project team has carried out in-depth cooperation with many domestic aviation manufacturing enterprises, and realized a variety of typical aviation sheet metal parts such as reinforced frame parts, asymmetric cone parts, half-pipe parts with curvature, and deep cavity rotary parts. The high-efficiency and high-quality forming covers the forming, punching and shape correction of aluminum alloys, aluminum-lithium alloys, titanium alloys and other low-plastic materials.

The appraisal committee unanimously agreed that: the project is technically difficult, highly innovative, has independent intellectual property rights, and the overall technology has reached the international advanced level, and agreed to pass the appraisal of scientific and technological achievements. The results of this project will provide technical support for high-efficiency, short-process, green and intelligent manufacturing of aviation high-performance lightweight components.