@Annihilation98 bro I know this is your way to stimulate a conversation and I applauded you for that, but you had been here for a year and had join with the discussion, please reread some of your post and the rebuttals, cause constant repetition , it gets tiring but for you I'll dig an article from last year for your perusal. The source is GLOBAL TIMES that is an official confirmation one can get.

Chinese firm to deliver 28nm chip manufacturing machine in 2021-2022: reports

Source:Global Times Published:

2020/6/7 17:13:40

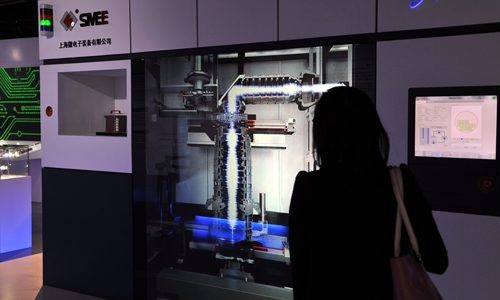

File photo: A visitor watches a Shanghai Micro Electronics Equipment (Group) Co display of how a lithography machine works on November 8, 2013.

Shanghai Micro Electronics Equipment (Group) Co (SMEE) will deliver the first domestic 28nm lithography machine between 2021 to 2022, helping narrowing the gap with the world's chip-making technology, industry websites said.

The move is a leapfrog breakthrough for China's semiconductor industry, according to domestic technology website mydrivers.com. Industry website icsmart.cn also reported it is good news for China's semiconductor industry chain.

The US crackdowns on ZTE and Huawei awakened Chinese companies to explore self-developed lithography equipment, which has underscored the urgency and significance of China to develop advanced chip making ability in a bid to avoid being squeezed by the US amid an escalating tech war.

Xiang Ligang, a veteran industry analyst, told the Global Times on Sunday that once SMEE has the ability to deliver 28nm lithography equipment, it will have the opportunity to move forward to 14nm and 7nm lithography equipment, noting that the breakthrough helps the company "accumulate experience" to manufacture high-end chip-making equipment.

The whole world could take part in the chip-making industry instead of a particular country or particular company, so progress by any single company is valuable, Xiang noted.

Founded in 2002, SMEE is one of the advanced lithography machine makers in China and accounts for about 80 percent of the domestic market share, industry websites said.

Lithography machines are one of the core pieces of equipment in chip manufacturing. Netherlands-based chip equipment maker Advanced Semiconductor Material Lithography (ASML) remained a global leader in churning out high-end lithography machines, followed by Nikon and Cano.

Liu Kun, a Beijing-based semiconductor industry analyst noted that even if the core component of the 28nm lithography equipment may not be made in China, it would be a breakthrough for the Chinese company to package such equipment.

It may take three to five years for companies like Semiconductor Manufacturing International Corporation (SMIC) to make the 28nm equipment by itself and there is still a long way to go, but Chinese companies are ramping up efforts, according to Liu.

Global Times